Wire Mesh Manufacturers

| WMM CHINA

| WMM CHINAChina Wire Mesh Manufacturers can help. Contact Us Now!

Wire Mesh

Wire Mesh

Home > Wire Products >

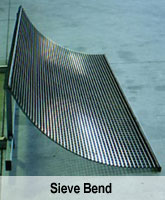

Wedge Wire Screen And Sieve Bend Screens

FROM Date:2007-11-30 Author :wiremesh

FROM Date:2007-11-30 Author :wiremesh SDespite the inherent design advantages of our sieve bends, some processes will tend to cause blinding or plugging problems. These can be quickly solved with mechanical rappers or vibrators. Unlike some systems, our assemblies have the vibration directed to the frame which holds the screen rather than to the screen itself. This avoids stresses on the screen which can lead to premature failure through breaking. The strong, rigid nature of our all-welded screen panels lets you apply vibration vigorously and and

effectively without risk of damage.

Our sieve bend assemblies are manufactured as standard units with an included angle of 45 O and a radius of 1018 mm for the 250 mm wide unit or a 2032 mm radius for 500, 750 or 1000 mm wide screens. Slot sizes range from 25 mm to super-fine 25 micron slot for the 120 0 DSM screens. Special order screens can be made wider to increase capacity; longer to increase effectiveness.

To determine the correct size sieve assembly, supply us with (1) particle size cut point, (2) feed rate, (3) Solids concentration and (4) maximum particle size or size distribution analysis.ieve Bend screens can be manufactured in a variety of widths, arc lengths, apertures or wedge wires to suit the flow rate and material being separated.

hough most applications require static “cross flow” sieve bends, “with flow” and vibrating Sieve Bends can also be manufactured.

|

In a typical feed situation the leading edge of the wedge wire removes the water and fine particles through the screen up to the cut point size, as the oversized particles move across the top of the screen. Static Sieve Bends require little or no maintenance in their operation and need only small floor areas in the plant and small head heights to operate. |

|

| AVAILABILITY RANGE | ||||||||||

|

Contact us Url: http://www.wire-product.com

Post your offers now!