Wire Mesh Manufacturers

| WMM CHINA

| WMM CHINAChina Wire Mesh Manufacturers can help. Contact Us Now!

Wire Mesh

Wire Mesh

Home > Wire Cloth >

Where wire cloth is used

FROM Date:2007-11-30 Author :wiremesh

FROM Date:2007-11-30 Author :wiremeshWhat is Wire Cloth?

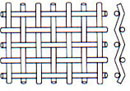

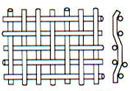

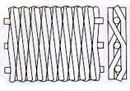

Wire cloth is a woven metal fabric having either  square or rectangular "working openings" between wires -- produced on large weaving machines called looms. "Working openings" are the clear spaces or distances between wires in both directions of each mesh of a square or rectangular woven fabric. Usually openings 1/4 inch and over are referred to as space cloth. Openings less than 1/4 inch are referred to as mesh cloth.

square or rectangular "working openings" between wires -- produced on large weaving machines called looms. "Working openings" are the clear spaces or distances between wires in both directions of each mesh of a square or rectangular woven fabric. Usually openings 1/4 inch and over are referred to as space cloth. Openings less than 1/4 inch are referred to as mesh cloth.

Square or Rectangular Opening.

The proper "working opening" depends primarily on the end application of the woven wire screen or cloth in service. For example, square openings should be used where accurate sizing is essential. Rectangular openings are usually three to four times longer than wide and offer increased "through" capacity with less separation accuracy. Elongated rectangular openings afford the highest "through" capacity with the least accuracy in separation.

|

|

|

|

Where wire cloth is used

* Grinding control of crushed materials * Sizing of material

* Scalping of material * Dewatering of material

* Filtering for removal of a decontaminate * Protection of an orifice

* Arrestor of flame or sparks * Shielding

* Containers for heat treating * Surface to support other filter medium

* Containers for cleaning * Medical implants

* Guards for animal, fans, machinery, windows, rooms, etc. * Strainers for pumps, pipelines, tanks, pools

* Drying of seed and solids * Catalysts for chemical reactions

* Burners for gas heaters * Grids for batteries, fuel cells

* Screen printing * Gas diffusion

WIRE CLOTH:

WIRE CLOTH DEFINTIONS

Bolting Cloth, Double Crimp, Inter-Crimp, Filter Cloth, Galvanizing, Market Grade, Mesh, Micronic Filter Cloth, Rectangular Mesh, Selvage, Shute, Space Cloth, Square Mesh, Warp...

CLICK HERE for more wire cloth definitions

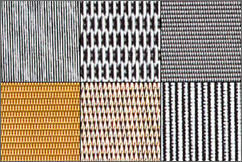

TYPES OF WIRE CLOTH WEAVES

Plain Weave, Twill Square Weave, Plain Dutch Weave, Twilled Dutch Weave...

CLICK HERE for more wire cloth weaves

ALLOYS

Our inventory consists of the following alloys: Stainless Steel Woven and Welded, Brass, Copper, Phosphor Bronze, Aluminum, Monel, Carbon Steel, Galvanized Steel...

CLICK HERE for more wire cloth metals

GALVANIZED WELDED AND WOVEN

Steel wire formed into a mesh. The material is passed through a hot galvanizing bath, which produces a highly resistant coatings, as well as bonding the wire together at the joints...

CLICK HERE for more galvanized welded

WIRE CLOTH SPECIFICATIONS

View our specification guide...

CLICK HERE for more wire cloth specifications

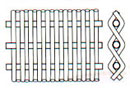

FILTER CLOTH AND RECTANGULAR MESH SPECIFICATIONS

View our specification guide...

CLICK HERE for more filter cloth & rectangular mesh specifications

Wire Cloth:

Woven wire cloth with its wide range of materials and weave patterns is an ideal medium for strainers and filters. Using available techniques, it can be worked and formed to exact filter requirements, combining durability, strength and reliability.

Specifying/Selecting Wire Cloth:

The most common properties used to specify wire cloth include material, mesh count, wire diameter and weave.

Material – The metal or alloy used in the wire to determine its resistance to corrosion, abrasion, heat and vibration.

Mesh Count – Refers to the number of openings per linear inch. The mesh is counted by starting from the center of one wire and counting the number of openings to a point one inch distant.

Wire Diameter – The diameter of the wire before weaving.

Weave - The pattern in which the wires running crosswise (Shute Wires) and the wires running lengthwise (Warp Wires) cross each other.

Pls comtact us Url: http://www.wirecloth.org

Post your offers now!